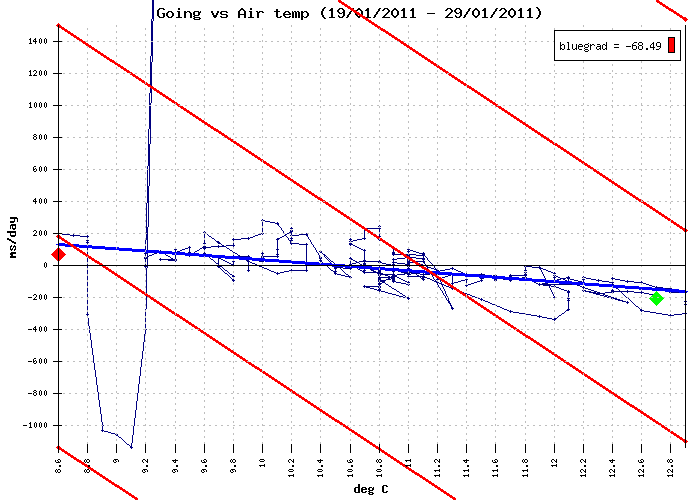

Best fit to data (blue line). Reference gradient (red lines):-605ms/day/deg C.

this is for an uncompensated steel pendulum -605ms/day/C (we hope to acheive within 10ms/day/C with compensation)

- 29 Jan 2011 [21:50]

- ADJUST: -150 ms/day to 30750 ... fine tuning. What better thing to be doing on a Saturday night!

- 29 Jan 2011 [16:50]

- ADJUST: +1100 ms/day to 30900 This change is needed because of the opening up of the pendulum chamber earlier today. Colder air is now drifting down to the base of the pendulum and this is where most of the temperature-compensating zinc is. It contracts on cooling, so lengthening the pendulum (that is how it works). So the clock has slowed down. Really by an astonishing amount. I suspect the air at the base of the pendulum chamber must have been really warm due to the central heating below, set at 22C The pendulum case sits high up in the room so it may well be up in the high 20s C. The temperature up in the clock room is around 6C today. Let us see how it settles down, but I think this will be a new operating regime. I wonder if the amplitude will do anything different now that air currents will be altered?

- 29 Jan 2011 [13:05]

- For the record, since I moved the weather station here are links to glitches that show the differential temperature effect have been happening often: [link] [link] [link] [link] [link] [link] [link] [link] . They all 1296306299 +0 point to a differential temperature effect of about 150 to 200 ms/day /C thus supporting the hypothesis presented here.

- 29 Jan 2011 [13:00]

- Having inserted the tube and opening up the chamber I am hoping we will see more uniform (and perhaps lower) temperatures down in the pendulum chamber and as a result I hope to see better temperature compensation.

- 29 Jan 2011 [12:35]

- Unfortunately I bumped the pendulum a few times while installing the tube - hence a few glitches.

- 29 Jan 2011 [12:30]

- I removed the boards at the top of the pendulum chamber and inserted a 1metre long 40mm tube down into the pendulum chamber with a view to encouraging cool air to descened, mix with and displace the warm air below (see photos [link] [link] thanks to Wu Hao). It has become clear that the cause of the apparent unsatisfactory temperature compensation is the fact that the lower half of the pendulum is about 2C warmer than the top half and this only occurs on very cold days. Here is an example [link] where changing tempurature of the lower half of the pendulum results in a change in going.

- 29 Jan 2011 [12:28]

- Here is my thinking on the errors of temperature compensation. On a cold day the clock case is about 1.5C colder than the pendulum chamber as was observed on the day I moved the weather station: [link] The ideally compensated pendulum has a zinc element 2/3 the length of the pendulum (for coeff expansion Zn/Fe = 30/12 ). The bottom of the zinc element is at the bob CoM (near enough) so the top 1/3 of the pendulum length is steel with no zinc.. A temperature differential T between top and bottom (colder at the top) gives a going change of + 0.5 * 1/3 * 12e-6 = + 172ms/day /C so the 1.5C observed difference will cause the clock to run 260ms/day faster. Recent data shows that the going in the recent cold weather is about 300ms/day faster than it was in milder times [link]

- 29 Jan 2011 [12:28]

- which is closely consistent with the calculation of 260 ms/day for the observed 1.5C temperature difference.

- 19 Jan 2011 [11:27]

- GLITCH power outage, this stopped the logging PC even though we have a UPS... Restarted at 12h45. I took the opportunity to install some proper weights for the fly (in brass 10.5 grams each, thanks to Mark Rainer for making these) so that it spins slower and impacts less on the escapement legs. This will help avoid reverse pigeon events. The amplitude dropped during the 4 minutes it took to install these.

Download data